ASAP - Electromagnetic suspended magnet

ASAP - Electro-aimant

ASAP - ELECTROMAGNETIC SUSPENDED MAGNET

Scope

The ferrous parts are withdrawn by switching off the power supply.

Scope

ASAPs suspended electromagnetic magnets with aluminium winding are fitted above conveyors, vibrating lines or chutes transporting bulk products.

They are very efficient when the plant has to be protected against ferro-magnetic parts and the products are magnetically refined.

ASAPs are specially suitable for processing bulk products, in average and thick layers of varied particle size.

Ferrous parts shall be in small or extraordinary quantities.

ASAPs are suitable for:

*recycling industries (wood, glass, plastic, cable,...),

*quarries, mines, cement plants

*recycling industries (wood, glass, plastic, cable,...),

*quarries, mines, cement plants

*Docks and harbours

*Food processing industries.

Technical specifications

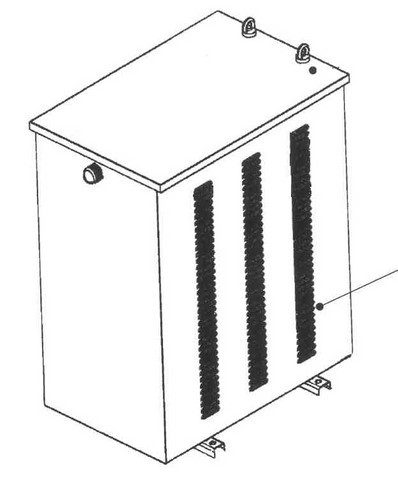

The magnetic circuit of ASAP consists of:

*a machine-welded steel yoke of high permeability

*external poles and a central steel core

*aluminum winding with reinforced insulation,

*and a closed non-magnetic box

ASAP is offered in two versions depending on use and environment:

*Air cooling: ASAP N,

*Oil cooling: ASAP NE.

Installation method

ASAPs can be suspended using chains, cables or strips and eyebolts with shackles.

*Food processing industries.

Technical specifications

The magnetic circuit of ASAP consists of:

*a machine-welded steel yoke of high permeability

*external poles and a central steel core

*aluminum winding with reinforced insulation,

*and a closed non-magnetic box

ASAP is offered in two versions depending on use and environment:

*Air cooling: ASAP N,

*Oil cooling: ASAP NE.

Installation method

ASAPs can be suspended using chains, cables or strips and eyebolts with shackles.

They are installed either crossways where the product unwinds or at conveyor chutes.

electric connections are made through terminal boxes.

Specifications

Performances vary according to various parameters:

*characteristics of the products to be processed,

*characteristics of the ferromagnetic elements to be extracted,

*characteristics of the installation.

Specifications

Performances vary according to various parameters:

*characteristics of the products to be processed,

*characteristics of the ferromagnetic elements to be extracted,

*characteristics of the installation.

8 types of ASAP in 2 different versions are offered depending on:

*working height: 210, 290, 370, 440, 520, 630, 750, 850 mm.

*cooling mode: N or NE.

*cooling mode: N or NE.

To help you make a choice, a questionnaire is attached in our document "IronRemoval"

Advantages

Simplicity of design ensures the reliability and performance of ASAP. The magnetic field is homogeneous over the entire working surface of the magnet.

The NE versions are perfectly dust and splash-proof.

Advantages

Simplicity of design ensures the reliability and performance of ASAP. The magnetic field is homogeneous over the entire working surface of the magnet.

The NE versions are perfectly dust and splash-proof.

The distribution and thermal dissipation are provided by oil bath. They are equipped with a safety valve and may be prepared for use in the tropics

Easily changed into overband, they can be adapted to changes in the production line.

Instruction for use

Instruction for use

The ferrous parts are withdrawn by switching off the power supply.

Maintenance is extremely reduced.